What Are the Risks of ESD?

- vidith cc

- Jul 15

- 3 min read

Understanding Electrostatic Discharge (ESD)

Electrostatic Discharge (ESD) is the sudden flow of electricity between two objects with different electrical charges. This discharge usually occurs when a charged person or object comes into contact with a conductive surface. Although ESD might feel like a harmless zap, it poses serious risks in sensitive environments, especially in electronics manufacturing, cleanrooms, and labs.

In these critical settings, ESD can damage expensive components, compromise product integrity, and lead to system failures. That’s why understanding and mitigating the risks of ESD is essential for any static-sensitive workspace.

Why ESD is Dangerous in Industrial Environments

Even low-voltage ESD events—sometimes below 100 volts—can damage microelectronic components without any visible signs. Often, latent ESD damage goes undetected during testing but causes failure later in the product's lifecycle. These hard-to-identify faults lead to high costs, poor reliability, and damaged reputation.

Key Risks of Electrostatic Discharge (ESD)

1. Damage to Sensitive Electronic Components

One of the most common risks of ESD is irreversible damage to microelectronics, including chips, transistors, and memory modules. These components are highly sensitive to static discharge and may fail immediately or degrade over time due to latent defects.

2. Product Failures and Quality Issues

Latent ESD damage can cause intermittent failures in the field, leading to customer dissatisfaction and warranty claims. These failures are hard to trace and often impact brand reputation.

3. Increased Scrap and Rework Costs

Components damaged by ESD may need to be scrapped or reworked, which increases material costs and labor. Over time, this leads to significant loss in manufacturing efficiency and higher production expenses.

4. Downtime and Equipment Malfunction

A single ESD event can cause a breakdown in test equipment or production machines. This can result in unscheduled downtime, delaying output and reducing operational productivity.

5. Safety Hazards in Explosive Environments

In facilities that handle flammable materials, ESD can ignite vapors or dust, creating serious fire and explosion risks. This is particularly important in chemical plants and pharmaceutical facilities.

6. Cleanroom Contamination

Static discharge attracts particles, compromising air cleanliness in cleanrooms. This leads to contamination risks in sterile environments like biotechnology or medical device production.

7. Non-Compliance with Industry Standards

Failure to implement ESD safety measures can violate compliance regulations like ANSI/ESD S20.20, resulting in failed audits or restrictions on certain contracts or certifications.

Areas at High Risk of ESD Damage

Electronics assembly stations

Semiconductor manufacturing floors

Server rooms and data centers

Testing and repair labs

Cleanrooms and pharmaceutical units

PCB fabrication lines

How to Minimize the Risk of ESD

Install conductive tiles, anti-static vinyl mats, and ESD epoxy flooring to safely ground charges.

Use ESD wrist straps, heel grounders, and ESD-safe gloves to dissipate charge from operators.

Equip workstations with ESD chairs, conductive benches, and static-dissipative table tops.

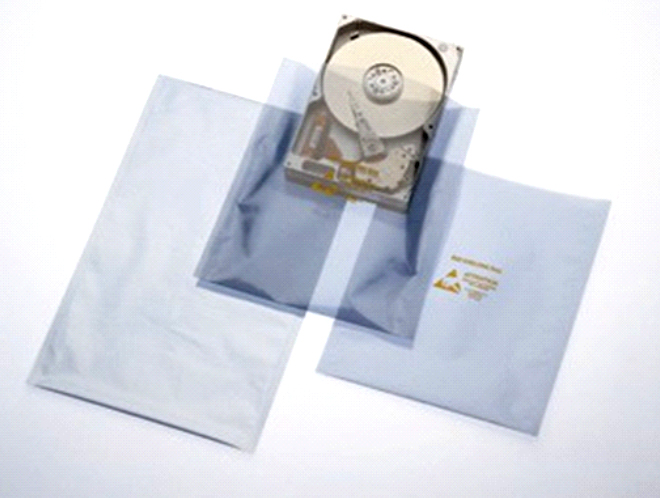

Use static shielding bags, ESD-safe bins, and conductive trays when transporting sensitive items.

5. Staff Training and Awareness

Regularly train employees on ESD awareness, safe handling of components, and how static is generated and discharged.

Conclusion: Take ESD Risks Seriously

While ESD might seem like a small concern, it has the power to derail entire production lines, destroy expensive equipment, and result in product recalls. Understanding the risks of ESD is the first step to implementing effective protection strategies. With the right ESD protection solutions, you can safeguard your equipment, ensure compliance, and maintain a high level of operational reliability.

%20(65).png)

Comments