ESD Tapes and Labels: Types, Uses, and Benefits

- Sep 3, 2025

- 2 min read

In the electronics industry, Electrostatic Discharge (ESD) can damage sensitive components, disrupt operations, and increase costs. That’s why manufacturers rely on ESD tapes and labels, specialized products designed to control static, ensure safety, and improve workplace compliance.

This guide explores the most commonly used ESD-safe tapes and labels, including conductive grid tape, floor marking tape, high temperature Kapton tape and ESD caution PP floor marking tape.

What Are ESD Tapes and Labels?

ESD tapes and labels are materials used in static-sensitive environments to prevent electrostatic build-up. They not only help protect delicate components but also make it easier to organize, label, and secure items in ESD-protected areas.

These products are widely used in:

Electronics manufacturing

Cleanrooms

PCB assembly

Semiconductor industries

Packaging and labeling of sensitive devices

Types of ESD Tapes and Labels

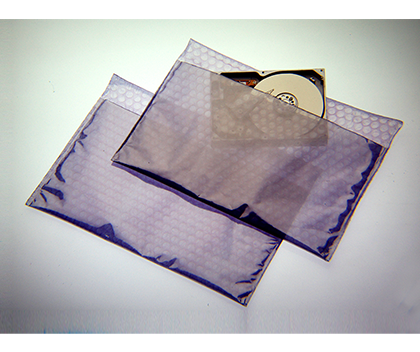

Conductive grid tape is designed with carbon-loaded grids that create a static-dissipative surface. It is often used for sealing ESD-safe bags and packaging materials.

Benefits:

Prevents electrostatic discharge during packaging

Strong adhesion without leaving residue

Ideal for sealing PCBs, chips, and electronic components

ESD floor marking tape is used to mark safe zones, walkways, and restricted areas in ESD-protected workplaces.

Benefits:

Clear identification of ESD-safe areas

Improves workplace organization

Prevents accidental movement of sensitive items

Kapton tape is made of polyimide film and is highly resistant to heat and chemicals. It is widely used in PCB soldering, insulation, and wave soldering processes.

Benefits:

Withstands extremely high temperatures

Provides insulation and protection

Leaves no residue after removal

This polypropylene-based tape is designed to warn and guide workers in ESD-sensitive zones. It often carries printed caution text or symbols for visibility.

Benefits:

Ensures compliance with ESD standards

Improves workplace safety

Easy to apply and remove

Why Choose ESD Tapes and Labels?

Prevent costly electrostatic damage

Ensure compliance with international ESD standards

Improve workplace safety and organization

Boost efficiency in cleanrooms and manufacturing

Frequently Asked Questions (FAQs)

Q1: What is the difference between conductive grid tape and Kapton tape?

Conductive grid tape is used for sealing and packaging ESD-sensitive items, while Kapton tape is used for high-temperature insulation in electronics manufacturing.

Q2: Can normal adhesive tapes be used in ESD-safe areas?

No. Regular tapes can generate static charges that may damage sensitive electronics. Only ESD-safe tapes are recommended.

Q3: Where should ESD floor marking tapes be applied?

They are typically applied in workstations, assembly areas, and walkways within ESD-protected zones.

Q4: Are ESD labels different from normal labels?

Yes. ESD labels are designed with static-dissipative materials to ensure they don’t create electrostatic discharge during use.

Final Thoughts

ESD tapes and labels are essential tools for maintaining a safe and compliant electronics manufacturing environment. From conductive grid tapes for packaging to Kapton tapes for high-heat applications and floor marking tapes for safety, these products play a critical role in preventing static-related damage.

By choosing the right type of tape for each application, companies can protect sensitive components, improve workplace safety, and maintain compliance with ESD standards.

%20(65).png)

Comments