The Shocking Truth About Static: How a Spark Destroyed a $10 Million Lab

- vidith cc

- Jun 4

- 2 min read

In the world of electronics and precision manufacturing, static electricity isn’t just annoying — it’s dangerous. Most people underestimate the destructive power of a tiny zap. But what if we told you that a single electrostatic discharge (ESD) incident once caused millions of dollars in damage?

This isn’t a myth. It’s a wake-up call.

Let’s dive into one of the most shocking ESD disasters in recent memory, what went wrong, and how businesses like yours can avoid a similar fate.

The Incident That Shocked the Industry

A Costly Mistake

A leading semiconductor lab in Asia — responsible for producing high-end microchips used in aircraft and defense systems — suffered a catastrophic event in 2019. A technician, unaware of his static charge, walked into a Class 100 cleanroom without proper grounding.

Within seconds, the static discharge from his body sparked a chain reaction that fried dozens of wafers in production, delayed shipping by weeks, and led to an estimated $10 million in losses.

No fire. No alarms. Just one invisible spark.

Why Did It Happen?

The ESD Protection Failures:

1. No Active Monitoring

There was no real-time wrist strap monitoring to ensure grounding continuity.

2. Improper Flooring

Only partial anti-static flooring was installed — and it had gaps.

3. Lack of Sticky Mats

There were no peelable sticky mats at the entrance, allowing charged particles in.

4. Inadequate Training

The technician assumed his gloves were enough protection — they weren’t.

This Can Happen to Any Business

Whether you’re handling PCBs, sensitive ICs, or packaging electronic parts, ESD is always a threat — especially when your protection systems are inconsistent or outdated.

Think your operation is safe? Here’s what ESD damage can silently cost you:

Lost Products

Each failed unit silently cuts into your profit margin.

Latent Defects

The worst kind — undetectable damage that causes failures weeks or months later.

Damaged Reputation

Late shipments and inconsistent quality can permanently hurt your credibility.

Regulatory Scrutiny

In industries like aerospace or medical devices, one ESD failure can attract unwanted audits or recalls.

How to Avoid a Multi-Million Dollar Mistake

The good news? You can protect your business from ESD damage with simple, affordable changes:

1. Install Peelable Sticky Mats

Trap charged particles at the entry point before they reach your workspace.

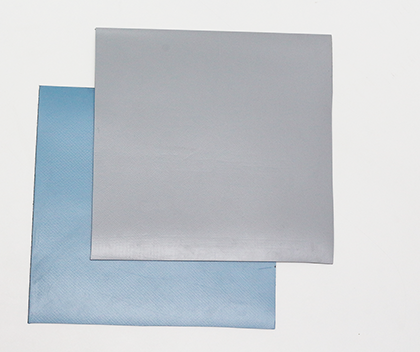

2. Use Static Shielding Bags

Package sensitive components safely during storage and shipping.

3. Equip Workstations with ESD Mats & Wrist Straps

And monitor them in real-time.

Static loves dry air — keep the environment above 40% RH if possible.

5. Train Your Team

A single untrained employee can undo your entire protection plan.

Final Words: Don’t Wait for a Disaster

If ESD hasn’t hit your bottom line yet, that doesn’t mean you’re safe — it may just mean the damage hasn’t shown itself yet. Invisible doesn’t mean harmless.

Your workspace should be treated like an operating room for electronics. At Highstar Technology, we provide the tools that protect your products, people, and profits.

%20(65).png)

Comments