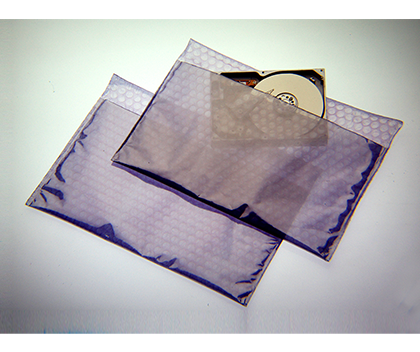

ESD Anti-Static Air Bubble Bag: Ultimate Protection for Sensitive Electronics

- Aug 27, 2025

- 3 min read

In today’s electronics manufacturing and cleanroom environments, protecting sensitive components from static electricity and physical damage is a top priority. One small electrostatic discharge (ESD) or minor impact can lead to costly failures, production downtime, and damaged products. That’s where the ESD Anti-Static Air Bubble Bag becomes an essential solution — offering both static protection and physical cushioning in a single package.

What Is an ESD Anti-Static Air Bubble Bag?

An ESD Anti-Static Air Bubble Bag is a specialized packaging solution designed to safely store, ship, and handle static-sensitive electronic components.

These bags combine anti-static materials with bubble cushioning to provide:

Static protection by neutralizing electrostatic charges

Physical shock absorption during handling and transportation

Contamination-free storage for delicate electronic assemblies

Commonly used in:

Printed Circuit Board (PCB) packaging

Semiconductor manufacturing

Hard disk drive protection

LCD, LED, and display panel shipping

Cleanroom assembly and storage operations

Why Are ESD Anti-Static Air Bubble Bags Important?

Electrostatic discharge can damage components even before they’re installed, making reliable packaging critical.

Using ordinary bubble wraps or plastic bags poses risks like:

Static buildup that damages sensitive microchips and circuits

Particle shedding leading to contamination in cleanrooms

Inadequate cushioning causing physical breakage during transit

With ESD Anti-Static Air Bubble Bags, manufacturers can:

Safeguard components from ESD damage

Protect products from scratches, dents, and impacts

Maintain compliance with industry safety standards

Types of ESD Anti-Static Air Bubble Bags

Different applications require different specifications. The most commonly used types include:

1. Open-Top ESD Air Bubble Bags

Ideal for storage in ESD-safe cabinets

Quick insertion and removal of components

2. Resealable ESD Bubble Bags

Equipped with zip locks for reusable applications

Best for frequent handling of parts

3. Pink Anti-Static Bubble Bags

Visibly distinguishable and commonly used in electronics packaging

Cost-effective solution for static protection

4. Moisture-Barrier ESD Bubble Bags

Protects components from humidity and static electricity

Ideal for sensitive semiconductor devices

Key Benefits of ESD Anti-Static Air Bubble Bags

✅ Dual Protection – Guards against both static discharge and physical damage

✅ Compliance Ready – Meets international ESD safety standards

✅ Durable & Lightweight – Ensures cost-effective shipping and storage

✅ Reusable Options – Reduces packaging waste and operational costs

✅ Versatile Applications – Suitable for semiconductors, PCBs, displays, and more

How to Choose the Right ESD Air Bubble Bag

Before selecting the right bag, consider:

Component Sensitivity – Match bag type to the level of ESD protection required

Storage vs. Shipping – Use thicker bubble bags for transportation

Moisture Concerns – Select moisture-barrier bubble bags for humidity-prone regions

Size & Fit – Ensure proper sizing for a secure, snug fit

Best Practices for Using ESD Air Bubble Bags

Always handle components using ESD-safe gloves

Store bags in ESD-protected workstations

Keep bags sealed to prevent contamination

Regularly check bags for wear or tears

Final Thoughts

The ESD Anti-Static Air Bubble Bag is more than just packaging — it’s an investment in product safety, quality assurance, and operational efficiency. Whether you’re shipping delicate PCBs, storing semiconductors, or safeguarding display panels, these bags ensure your components remain safe, clean, and static-free at every stage.

FAQs

Q1: Can I use regular bubble wraps instead of ESD air bubble bags?

No, regular bubble wraps generate static and can damage sensitive components.

Q2: Are ESD air bubble bags reusable?

Yes, resealable and zip-lock models are designed for multiple uses without compromising protection.

Q3: Do these bags work without ESD flooring and workstations?

They provide standalone protection but are most effective when used with other ESD-safe infrastructure.

%20(65).png)

Comments